Mining Vehicles: Giant Machines in the Mining World

Mining vehicles, a marvel of engineering in the mining area, have become the backbone of the industry. They operate on a large scale and become essential symbols in the field. This article will explore the various types and crucial roles of mining vehicles in the coal industry.

If you have ever visited a mining area, you have seen large mining vehicles passing by the site. As operational vehicles in area mining, of course, the cars used are designed to be large enough to suit the needs of the field.

Why are mining vehicles so large?

Mining vehicles are generally huge because they are designed to handle heavy loads and harsh working conditions in mining environments. The power produced is immense with a large-capacity engine. Thus, such vehicles can be relied on in challenging mining terrain.

Its large size can certainly amaze many people. It is so big that there are also mining cars whose height is equivalent to a three-story house. Large trucks like this also sometimes ply the highway to transport tons of mining products to be moved to their destination.

Types and Functions of Mining Sector Vehicles

Of the many types of vehicles used for mining, there are several kinds, and the functions of mining operational vehicles are as follows:

1. Dump Truck

This heavy equipment is usually used to move large amounts of mining material and is traditionally used to move materials such as sand, stone, gravel, or renovated materials.

Generally, two types of dumps are often used: namely rigidcks and articulated and articulated

2. Underground Rock Drill Vehicle

This tool is a unique tool that can facilitate construction carried out in underground mining areas. This equipment can drill deep into the ground with a unique, powerful engine and is usually used for excavation projects with a relatively high difficulty level.

This mining vehicle has at least three models often marketed, namely single, double, and three-boom hydraulic pilot. All three have a high function and quality and are helpful as short-term drilling technical aids.

3. Scraper

This heavy equipment is usually used in mining to remove or move gravel, dirt, and other materials.

This tool is used specifically to clean the surface of the soil so that it is free from unwanted materials. This tool can work effectively and efficiently in poor or challenging soil conditions.

One of the advantages of this tool is its ability to remove dirt in the form of wet soil on the surface. This differs from other types of heavy equipment, requiring workers to wait for the damp ground to dry before they can operate.

4. Bucket Wheel Excavator

This is heavy mining equipment that can run continuously for large-scale excavations. This tool can replace materials such as gravel, rocks, soil, and other materials in mining.

Bucket wheel excavator has an excavation capacity of up to 20,000 m3/hour or 7,000 tons/hour. This tool is generally connected to the production system cross-pit spreader or belt conveyor. The working principle of this tool is that the bucket will work and move the excavated material into the system belt conveyor.

For your use, you can adjust it to field conditions. For example, suppose the condition of the mining land is not very good, or mining activities are relatively rare. In that case, it is recommended to use a bucket wheel excavator with a smaller size.

However, if the mining land is flatter and mining activities are more frequent, you can use a larger size.

5. Large Dozer

This tool is a tractor-type mining vehicle that uses chains and is equipped with a blade at the front. This vehicle is usually used for digging, pulling, and pushing materials at mining sites.

Apart from the blade, which is standard equipment on this vehicle, there is also other additional equipment that is commonly used in the form of:

- A ripper, a tool used to dismantle material that cannot be excavated, is usually needed for road construction or mining work.

- A winch is a tool used to pull material. This tool is often used for wood removal work in the forest.

Usually, large dozers are used in coal mining and function to level the ground, uproot trees, or dig up the ground when clearing land.

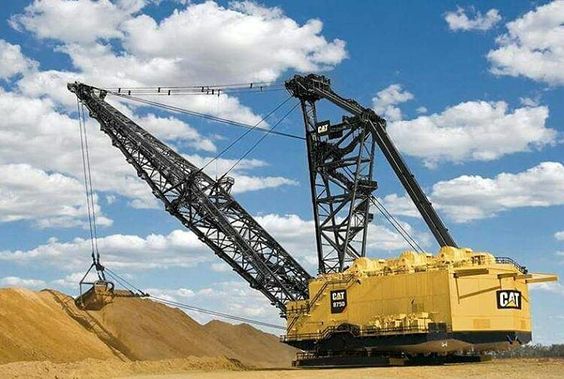

6. Dragline

This tool is usually used to dig soil and also load materials. Power shovels with 2.5 cu-yd capacity can be converted into a dragline. The way to do this is by letting Goboom shovel and then replace it with a bucket dragline.

A dragline is a large vehicle that functions as a material mover in large quantities and can be more effective.

Due to its flexible rope curler, this tool can perform at much greater distances and depths than other types of machines.

You will usually find this tool in river dredging because it is suitable for use in places full of water or muddy.

7. Crane

This type of tool can lift and move large amounts of material. This tool also has the shape and ability to raise large loads and can rotate 360 degrees with a range of up to tens of meters.

Crane is usually used for project work, workshops, warehousing, ports, and storage. This tool consists of several types: tower crane, mobile crane, crawler crane, hoist crane, and many more.

8. Manhauler

Another type of mining vehicle is the manhauler, a heavy vehicle designed to transport employees in mining areas. This tool was chosen because its initial chassis shape was intended for rough terrain conditions.

This tool has a strong frame structure and has been certified as a rollover protection structure (ROPS). The deck floor uses marine wood, which is water-resistant. Plus, there is a drainage system, and the body is made of aluminum, so it doesn’t rust and is durable.

9. Excavator

This is one of the many heavy equipment that uses diesel power to excavate land. Partbucket, located at the front, functions to make holes, excavations, or trenches.

Excavating using this tool is indeed very suitable for the mining industry. The bucket at the front can also be replaced and adjusted to suit your needs. By changing the shapebucket, later users can carry out various types of work.

Unlike the previous type, the excavator, The latest release can operate using a hydraulic system, making it easier to manage, just like the earlier tools.

Not only do they understand the types of mining vehicles, but mining companies also need to pay attention to coal commodities. SUCOFINDO provides testing services to determine the quality of coal.

Service Mining safety management system This starts from the Upstream to Downstream stages to regulate the management of mineral and coal mining safety and a mining safety management system specifically for processing and/or refining. For more details, you can find complete information about the service by visiting the page SUCOFINDO! Contact us for more detailed information here.